Service Hotline

+86 0755-2372 9158

+86 13510477647

Service HotlineService Hotline

+86 135 1047 7647

Source: Time:2022-08-04 17:23:20 views:

Author/Shenzhen Taiwa Energy Technology Co., Ltd.

Keywords: water cold storage, water energy storage, both fire-fighting and cold storage, concrete structure water cooling system

Abstract: Concrete structure water cooling system is the most widely used energy storage form in the industry. Concrete structure water cooling system is suitable for new buildings and old buildings. There are two main manifestations. The electricity price period in Pinggu and the temperature difference of cold storage are calculated, and a concrete structure pool of corresponding volume is newly dug for cold storage. The second is to use the original fire-fighting pool or expand the capacity on the basis of the original fire-fighting pool, and adopt the form of combining fire-fighting and cold storage functions to realize an energy storage system with multiple and high-grade utilization of building space and functions. Shenzhen Taiwa Energy Technology Co., Ltd. has implemented a number of water cooling system projects with concrete pool structures in the water cooling industry, and has accumulated rich experience in each process and process. The corresponding content is shared as follows:

Geological adaptability of concrete pool structure water storage system:

In construction, the engineering geological classification divides soil and rock into eight categories according to the hardness of soil and rock and the difficulty of construction and excavation, namely soft soil, ordinary soil, firm soil, gravel and firm soil, soft stone, sub-hard stone, and hard stone. , Extra hard stone. Different geological conditions correspond to different degrees of solidity, which requires different requirements on the number and density of piles for the structural load-bearing of the pool construction, especially the pile foundation. Table 1 shows the excavation difficulty coefficients corresponding to the soil and rock in the engineering geology.

|

Classification of soil |

soil name |

solidity factor f |

Density (kg/m³) |

level of soil |

|

A class of soil

|

Sand, silt, alluvial sand; loose planting soil, silt (peat) |

0.5~0.6 |

600~1500 |

Ⅰ |

|

|

||||

|

second class soil |

Silty clay; moist loess; sand mixed with gravel and pebbles; silty mixed egg (crushed) stone; planting soil, filling soil |

0.6~0.8 |

1100~1600 |

Ⅱ |

|

|

||||

|

three types of soil |

Soft and moderately dense clays; heavy silty clays, gravel soils; dry loess, loess with crushed pebbles, silty clays, compacted fills |

0.8~1.0 |

1750~1900 |

Ⅲ |

|

|

||||

|

four types of soil |

Hard and dense cohesive soil or loess; sweat crushed stone, pebbles, moderately dense cohesive soil or loess; coarse pebbles; natural graded gravel; soft marl |

1.0~1.5 |

1900 |

Ⅳ |

|

|

||||

|

five types of soil |

Hard clay; medium dense shale, marl, chalk; loosely cemented conglomerate; soft limestone and shell limestone |

1.5~4.0 |

1100~2700 |

Ⅴ~Ⅵ |

|

|

||||

|

Six types of soil |

Mudstone, sandstone, conglomerate; solid shale, marl, dense limestone; weathered granite, gneiss, and syenite |

4.0~10.0 |

2200~2900 |

Ⅶ~Ⅸ |

|

|

||||

|

seven types of soil |

Marble, diabase; porphyrite; coarse and medium-grained granite; solid dolomite, sandstone, conglomerate, gneiss, limestone; lightly weathered andesite, basalt |

10.0~18.0 |

2500~3100 |

Ⅹ~ⅫⅠ |

|

|

||||

|

Eight types of soil |

Andesite, basalt; granite gneiss; solid fine-grained granite, diorite, quartzite, gabbro, diabase, porphyrite, amphibole |

18.0~25.0 |

2700~3300 |

ⅪⅤ~ⅩⅥ |

|

above |

Table 1

For the above engineering geology, concrete energy storage tanks can be built. In case of the presence of quicksand, muddy or even dark rivers in the geology, it is not recommended to use the concrete tank structure for cold storage. In addition to cost factors, there is also structural safety. Sexual issues.

Features of concrete pool structure water storage system:

According to the location of the project and the nature and function of the project, the concrete structure energy storage tank can adopt the mode of cold storage in summer and heat storage in winter. At the same time, the new project can also consider expanding the volume on the basis of the original fire tank to maximize the utilization of storage tanks. Energy pool, while reducing construction cost, saves operating electricity cost to the greatest extent. If the hot and cold storage mode is adopted, it is necessary to make corresponding choices on the materials for waterproofing, heat preservation, water distributor, etc. during the construction of the energy storage tank.

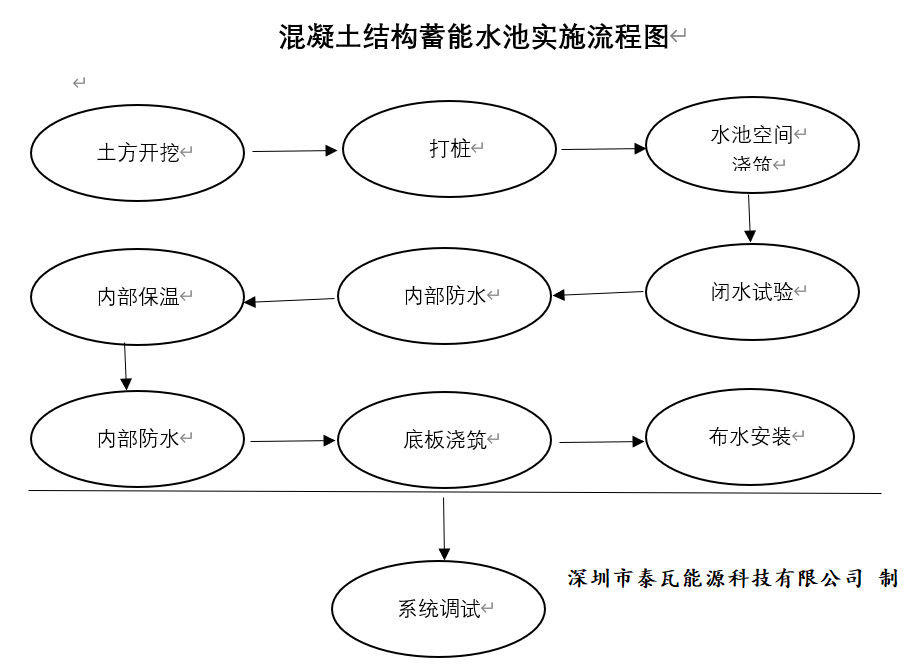

Concrete pool structure water storage system construction process:

Table 2

For the construction of an energy storage tank, if it is a new project, it is first necessary to conduct geological survey and calculate the structural load on the structure. During the civil construction process, a pool space is excavated or built separately. During the construction of the pool, it is necessary to do the same. The exterior of a good pool is waterproof, such protection is to prevent external water from penetrating into the storage pool.

After the concrete structure of the energy storage tank is completed, a closed water test needs to be carried out to check the tightness and waterproof performance of the tank, and no leakage is qualified. After the closed water test is completed, the internal waterproof construction begins. At present, JS materials are mostly used in the market for waterproofing. The construction thickness must reach 3MM, and then the insulation construction is carried out. At present, the best insulation method is to use polyurethane seamless foaming. Thickness requirements According to the water supply and return temperature and structural characteristics of the pool, different thickness requirements are used, and a layer of waterproofing is made on the top of the insulation layer. This waterproofing layer has high requirements on the elongation rate and fracture resistance of the material, and needs to choose a good material, such as polyurea . The waterproofing of this layer is very important, and it must be ensured that there is no leakage. Otherwise, when running for a long time after irrigation, the insulation layer will fail due to water infiltration into the insulation layer. After the waterproof construction is completed, the concrete layer is finally poured on the bottom layer. So far, the construction of the main body of the energy storage tank has been completed.

Concrete pool structure water storage system water distribution:

The water distributor is the key to the entire energy storage tank, which directly affects the specific technical parameters such as the cold storage efficiency, the total amount of cold storage, the thermocline layer, and the heat exchange margin. A direct key component that directly determines whether the entire water storage system is used with high quality and efficiency. The key to the water distribution of the water storage system is the density of the water distribution, the uniformity of the water outlet and the smaller the turbulence, the better. This requires strict requirements on the material of the water distributor, the internal structure and performance of the water distributor. Require. According to industry norms, H-type octagonal water distributor has become the most recognized water distribution method in the industry due to its unique characteristics of voltage stabilization, diversion, and multi-stage water distribution.

Acceptance of concrete pool structure water storage system:

The acceptance of the water energy storage system, whether it is a concrete structure or a steel cold storage tank structure, the acceptance method is the same, and the acceptance is carried out together with the entire HVAC project. The internal parameters of the tank are mainly the parameters and systems such as the oblique temperature layer and the total amount of cold storage. The stability of operation is checked and accepted. Acceptance is mainly based on the requirements of the bidding documents and design drawings.